Real-time particle sizing for cement and other dry powders from 0.25 µm to 1,750 µm with laser diffraction and two-stage sampling

Together with the representative sampling with MIXER, the laser diffraction sensor MYTOS forms a robust on-line process analysis system that has proved itself in harsh environments such as the cement grinding process. Primary screw or air slide samplers initially take a subsample off from the main process line. During the secondary sampling with MIXER, a small partial amount is extracted as a representative analysis sample and fed to the laser granulometry. Thanks to the use of the integrated RODOS dry dispersion in the MYTOS system, even finest, cohesive powders can be reliably dispersed and measured. The interplay between multi-stage sampling, dispersion and laser diffraction sensing enables real-time analyses of dry powders with particle sizes ranging from 0.25 µm to 1,750 µm in process lines with mass flow rates from 20 t/h to over 500 t/h. The optionally clocked or continuous recording of measured data supports integrated quality inspection and optimised process control.

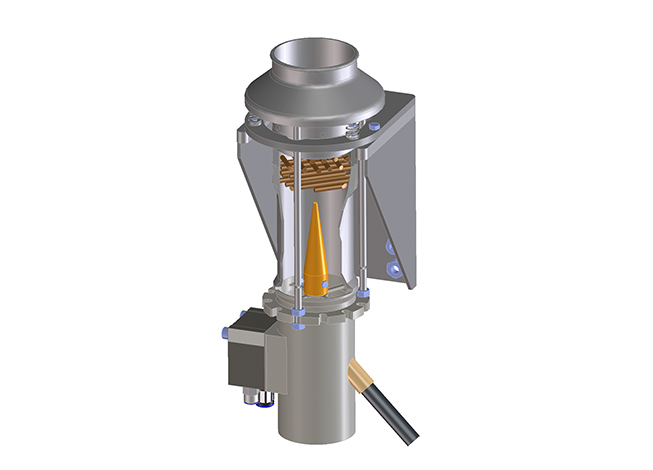

For the on-line particle size analysis in grinding processes for cement or anode coke, robust screw conveyors or air slide samplers are often used for sampling. They branch off a partial stream with a throughput of typically 30 kg/h to 50 kg/h from the main mass flow. The sample amount extracted in this way is still much too large for the laser diffraction method and therefore needs to be reduced further. In the bypass line, the subsample is fed into the MIXER for the secondary sampling. The product, which is distributed across the 60 mm pipe cross-section, is randomly mixed and homogenised through a sequence of coarse bar gratings. A static probe positioned centrally in the pipe extracts from this uniformly distributed product stream a representative analysis sample of just a few grams, which is suitable for laser granulometry (for cement: approx. 2 g to 5 g). For adjustment of the sample amount, there are five different probe tips ranging from 1.5 mm to 2.5 mm inlet diameter. A pneumatic oscillator generates vibrations that ensure unobstructed transportation of the product and dedusting of the MIXER sampling. An integrated blow-back device keeps the entire system free of residues, enables particle-free reference measurements and prevents the risk of eventual cross-contamination.

The particular subsample is fed into the MYTOS system, which is installed close to the process, and dispersed in the downstream RODOS injector and measured in the measuring zone of the MYTOS laser diffraction system in the free aerosol jet. Measurement results are generated either continuously in real-time with a resolution in the range of milliseconds, or sampling of the process and measurements are conducted in regular time intervals. The information gained about the particle size distribution is made available via standard communication interfaces to a process control system for monitoring or for process control. After measurement, the sample can optionally be returned to the process, disposed of via an extraction system or collected for further analyses via a cyclonic separation.

Customization to the specific process environment and to the products that are to be measured is achieved in close cooperation with your process engineers and our experienced engineering team.

- Particle size and particle size distribution

- For dry, fine grained and also cohesive powders

- For clocked or continuous real-time analyses at the process | on-line

- 6 high-resolution measuring ranges from 0.25 µm to 1,750 µm | R2 to R7

- Sampling of a partial flow from the main process line | Screw sampler…

- Extraction of a representative analysis sample from the partial flow | MIXER

- Adaptable probe tips for adjustment of the sample amount

- Safe, reliable sample throughput and continuous dedusting through vibration

- Connection to process control systems | TCP/IP, OPC, Modbus®, Profibus®, PLC signals

- Monitoring of multiple process lines with a single sensor | Multiplex installation

Typical APPLIcATION

All on-line systems can be optionally equipped with a manual sample feed, which comprises the vibratory feeder VIBRI and a stainless steel hopper. The systems are equipped with a VIBRI platform and the corresponding connections as standard. The hopper is mounted with a clamp connection onto the sensor system in place of the hose line of the sampler. This upgrade enables manual off-line measurements and is also required for re-certification of the systems with reference material.

In cases where particle size needs to be monitored on multiple process lines, the capturing of measurement data can be done with just one MYTOS laser diffraction system and multiple samplers installed in the different lines. Sequential sampling provides the sensor with samples from the different lines one after the other via a collector. Fast measurement and cleaning cycles effectively prevent the risk of cross-contamination during processing of the individual samples from different origins.