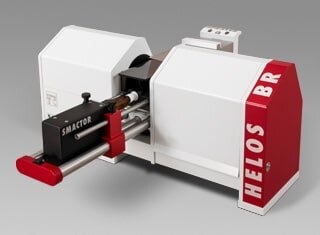

Unit for actuation of pump sprays for droplet size characterization within generated spray cones

The SPRAYER is a versatile adapter for nasal and pharyngeal pump sprays designed to measure droplet size distributions using the HELOS laser diffraction sensor. As the results are usually depending on a variety of parameters driving the spraying process, e.g. the force or the stroke-velocity behaviour, the distance to the measuring zone or the inclination of the spray bottle to the horizontal, the spraying process has to be performed under controlled reproducible conditions.

With the intelligent SMACTOR actuator, the SPRAYER supports both stroke-acceleration and force-controlled actuation and simulates manual release. With a variety of individually assignable parameters such as acceleration, maximum velocity, path length, maximum force and their rise time, the actuator enables user-defined and reproducible release profiles.

The combination of SPRAYER and SMACTOR in a robust design provides user-friendly sensor-monitored operation, ensuring fast and precise positioning of the nose spray bottle to the laser beam in the measurement zone.

The complete actuation process is controlled and monitored by software for subsequent evaluation. The distance of the spray's nozzle to the laser is software-controlled.

The monitoring of the measurement can be performed by the application software in four different modes:

- Integration of the diffraction intensities over the complete spray process

- Separation of the results in three phases: formulation phase, stable phase, dissipative phase, as requested by e.g. the FDA

- Time resolved measurements with definable resolution up to 2,000 particle size distributions per second

- Time-segmented measurements with subsequent identification of the stable phase and summary of the corresponding segment for evaluation

For the operation an extraction unit is required for sample collection and the generation of a laminar air flow in the measuring zone of the HELOS. The SPRAYER is only available in combination with the actuator SMACTOR. However, SMACTOR can also be used independently of the SPRAYER in combination with a universal rack for particle and droplet size analysis of a wide range of different bottle types. The tilting angle of the HELOS & SPRAYER system and the actuation angle of the spray bottle are monitored by the SPRAYER and set up using the optionally available ROTOR.

SPRAYER and ROTOR master the activation of sprays under angles from 0° to 90° in steps of 5°. Together with the laser diffraction sensor HELOS/BR, the complete system lifts automatically and turns to the desired angle. A sensor integrated in the SPRAYER transmits the angle of inclination to the evaluation software.

The SMACTOR actuator can be used in combination with a universal rack independently of the SPRAYER in free experimental set-ups in the HELOS/KR-Vario. The universal rack with spring-loaded holding mechanism is flexibly adjusted to many different types of bottles, such as MDI, pump or propellant gas bottles and enables a variety of different spray applications.