Powerful sensor technologies for particle sizing

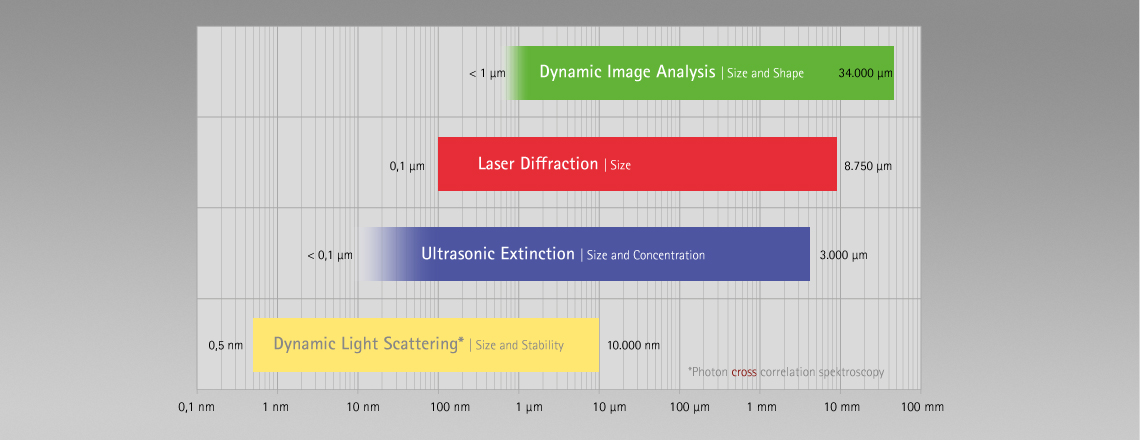

Our innovative sensor technologies enable powerful and reliable analysis systems to determine the relevant physical measurements which characterise the properties of disperse particle systems. Key measurement values are particle size and particle shape, as well as their distribution. We cover a unique size range from less than one nanometre to over 30 millimetres. Continually innovating, we contribute significantly to the further development of particle measurement technology in the areas of laser diffraction, dynamic image analysis, ultrasonic extinction and photon cross-correlation. We offer more than just lab applications (off-line); we also work to create further potential applications for our technologies in automated laboratories (at-line) and directly in production for real-time analyses in and around the process (in-line and on-line).

The physical measuring principle of each sensor technology has a decisive influence on the instrument design. We maintain a modular system architecture that can be adjusted flexibly for each application as appropriate to the product, so that the products to be investigated do not require elaborate sample preparation in order to fit with the system. Our aim is the measurement of particle systems in their original state. This is achieved through a wide range of dispersion systems and dosing unit options for our HELOS laser diffraction, and dynamic image analysis with QICPIC. The sensor is the heart of the measuring system. Its optical bench defines the integration concept for optional changeable lenses, dispersers and dosing units. The evaluation and management software, which integrates and manages all system components as well as the peripherals, is also part of the central system architecture. Our powerful application software is the shared platform for all the sensor technologies in use.

Laser diffraction, dynamic image analysis and dynamic light scattering are all optical procedures that require a suitable, optically transparent particle concentration in order to produce reliable measurement results. Ultrasonic extinction, an acoustic procedure, complements our selection, and enables even optically opaque suspensions and emulsions to be measured in their original state without elaborate dilution processes. All sensor technologies work according to the same basic principle: optical or acoustic waves are brought into interaction with dispersed individual particles, and from that interaction they deliver information about the physical properties of the disperse particle systems.