Particle size analysis with laser diffraction method

Over the past 50 years Laser Diffraction has developed into the leading principle for particle size analysis of all kinds of powders, suspensions, emulsions, aerosols and sprays in laboratory and process environments.

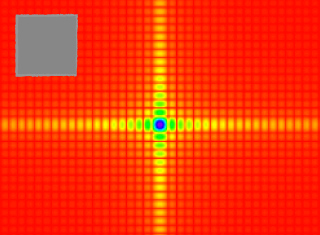

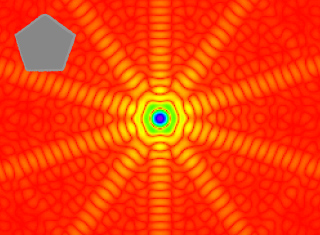

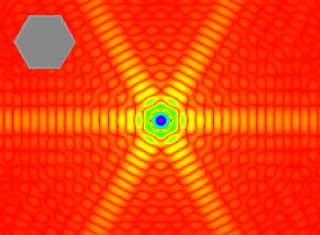

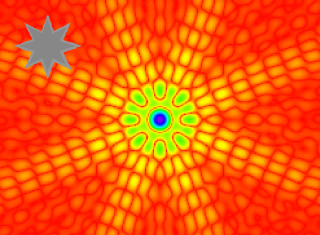

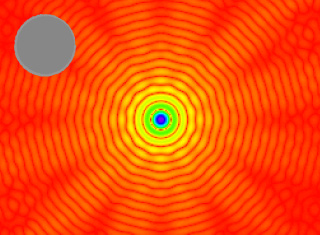

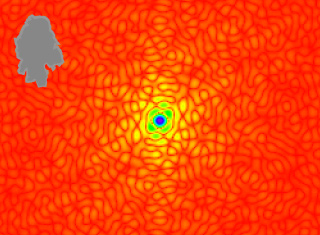

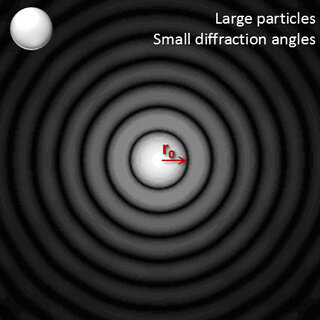

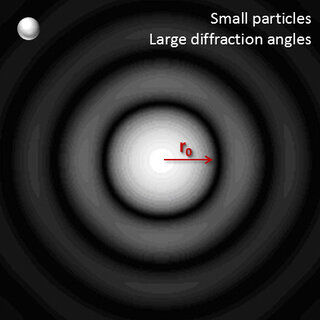

The diffraction of the laser light results from the interaction of the light with the particles and can be described mathematically by Fraunhofer or Mie theory. For a single spherical particle, the diffraction pattern shows a typical ring structure. The distance r0 of the first minimum to the centre is depending on the particle size, as shown in fig. 1 and fig. 2. The acquisition of the intensity distribution of the diffracted light is usually performed with the help of a multi-element photo-detector, as displayed in fig. 3.

The scattering of unpolarized laser light by a single spherical particle can be mathematically described by

I(θ) is the total scattered intensity as function of angle θ with respect to the forward direction

I0 is the illuminating intensity

k is the wavenumber 2π/λ

a is the distance from the scatterer to the detector and

S1(θ) and S2(θ) are dimensionless, complex functions describing the change of amplitude in the perpendicular and the parallel polarized light.

Different algorithms have been developed to calculate I(θ). The Lorenz-Mie theory is based on the assumption of spherical, isotropic and homogenous particles and that all particles can be described by a common complex refractive index m = n-ik of the material. The refractive index m has to be precisely known for the evaluation which is difficult in practice especially for the imaginary part k, and inapplicable for mixtures with components having different refractive indices.

The Fraunhofer theory considers only the diffraction at the contour of the particle in the near-forward direction. No pre-knowledge of the refractive index is required and I(θ) simplifies to the following formula with the dimensionless size parameter α=πx/λ. This theory does not predict polarization or account for light transmission through the particle.

Following the premise of Fraunhofer diffraction scattered light of absorbing particles is measured under low angles in forward direction only. In contrast to Mie theory only the Fraunhofer model does not require knowledge of optical properties. Hence, solely Fraunhofer is applicable to mixtures of different materials and shapes. With laser diffraction the determined particle size always refers to the equivalent diameter of a sphere sharing the same diffraction pattern.

Simultaneous diffraction on more than one particle results in a superposition of the diffraction patterns of the individual particles as long as the diffraction between the particles can be neglected. In 1983 Sympatec has pioneered in evaluating the size distribution with a parameter free and model independent mathematical algorithm. This has been accomplished with the introduction of the Phillips-Twomey algorithm for the inversion process.

Diffraction Patterns of non-spherical Particles

Calculated diffraction patterns for non-spherical particles (please refer to the grey particle shape in the corresponding image). All patterns show a symmetry of 180°.