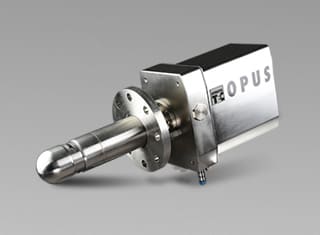

Particle size analysis of less than 0.1 µm to 3,000 µm in highly concentrated suspensions and emulsions with ultrasonic extinction in the compact laboratory device

The compact table-top measurement instrument NIMBUS is the efficient implementation of the tried and tested ultrasonic extinction technology for the analysis of individual fluid samples with low viscosity in the laboratory. The acoustic measurement process offers outstanding capabilities for particle size analysis of less than 0.1 µm to 3,000 µm, even in highly concentrated suspensions and emulsions that are not directly accessible to light-optical methods. Using sound waves means that analyses can be performed in their original state regardless of the transparency of the material system – without dilution or extensive sample preparation. NIMBUS holds between 250 ml and 1,000 ml and carefully circulates the sample volume in a controlled circuit. The sample is scanned with low-energetic ultrasound in the flow measuring cell. Depending on the product, the system supplies a particle size distribution resolved across 31 categories every 1 to 2 minutes and determines the concentration of disperse solids or droplets, respectively.

The particular strength of the ultrasonic extinction is the use of an acoustic measuring principle. The sound waves are coupled into the suspension or emulsion to be analysed via a piezoelectric high-frequency transducer as a scan with 31 discrete frequencies. After travelling through the dispersion, the sound energy is collected via a second piezoelectric transducer. The so-called attenuation or also ultrasonic extinction results from the ratio of coupled-to-received energy. A particle or droplet size distribution with 31 reference points is calculated from the measurement of the attenuation spectrum with a resolution of 31 values. The extinction function required for the evaluation depends on the material and is determined during device setup and stored in the NIMBUS system for each sample type to be measured. Due to the mechanical and electrical stability of the sensor, NIMBUS is then permanently ready for measuring the preset sample types and requires no further calibration.

A carefully operating centrifugal pump in the NIMBUS measuring circuit ensures continuous circulation and dispersion of the sample. The sample is guided in a stainless steel piping on a short path from the storage tank through the measurement zone to ensure a consistently high-quality analysis without material build-up or sample carryover. Thanks to the lowerable bottom of the basin, quick draining and cleaning are possible in just a few seconds.

The analysis of a continuously circulating sample is initiated via mouse click in the control and evaluation software. After completion of a frequency run, the analysis results automatically appear as particle size distribution, trend graph (for long-term analyses) or individual measurement values in a table.

NIMBUS is a robust measuring system with a high chemical resistance to aggressive media, and is used at product temperatures up to 50°C. All components coming into contact with products are adapted to the respective requirements and are designed in resistant materials: Measurement zone, piping and storage tank made of stainless steel (types 1.4571 | 1.4308 | 1.4301 | 1.4112), acoustic windows made of vitreous carbon (Sigradur®) and seals made of FKM (optionally EPDM, NBR, FFKM (Kalrez®)). Further mechanically stressed parts are made of durable PTFE (Teflon™) or polyamide 12 G.

- Particle size, particle size distribution and concentration

- For fluid suspensions and emulsions with particle concentrations up to 40 volume percent

- For analyses in laboratories | off-line

- Highly resolution measuring range from < 0.1 µm to 3,000 µm | 31 measuring points

- Analysis volume of 250 ml to 1,000 ml in a closed sample circuit

- No extensive sample preparation | Measuring the sample in its original state