With laser diffraction the particle size distribution is determined by the characteristic diffraction pattern of a particle collective. In contrast, image analysis captures the physical properties of each single particle. The distribution of a property such as size or shape descriptor can thus be resolved in nearly any class. With image analysis even smallest amounts of over or under sized particles may be detected. Even single particles with specific geometric properties such as aggregates, fractures or foreign particles are traceable. Image analysis operates in a similar way to a modern microscope: a digital camera with special optics captures the particles within the frame. Physical information about particle properties is transmitted to a computer. For each single particle in the image size and shape descriptors are determined by evaluation software.

Considering dynamic image analysis the particles are streaming continuously through the measuring volume controlled by the camera. The free movement leads to random orientation of the particles. From the different perspectives their actual shape and size distribution can be accurately determined. With a continuous feed of dispersed particles reliable and representative results are achieved based on a statistically significant number of particles. By closely controlling the concentration of the particle flow the overlay of particles is prevented.

Learn more about dynamic image analysis

Our solution with QICPIC and PICTOS

The basic concept is the combination of well-established powerful disperser RODOS with dynamic image analysis (DIA). A well dispersed particle flow is led through the image plane. Due to the dispersion the particles are separated from each other by the transportation fluid and overlapping particles are widely avoided. So high particle numbers per image frame can be captured.

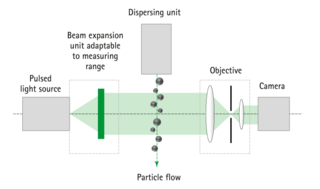

As the particles are accelerated by the dispersion process, attention has to be paid to a possible motion blur. Commercially available flash lamps with exposure times of typical 100 µs cannot be used, as the motion blur would be as much as 10 mm for particles velocities of 100 m/s. So Sympatec has developed a special pulsed light source with an exposure time of less than 1 ns resulting in a motion blur of only 100 nm for the same velocity. This is below the smallest pixel size of 0.55 µm and invisible for the camera. So this method has the appearance of a static image analysis.

In order to detect the edges of the particle precisely, the particle flow is imaged in transmission using a special imaging objective, which only transmits light rays to the camera which are nearly parallel to the optical axis. In combination with a parallel illumination, even highly transparent particles are imaged 'black', as long as their diffraction index differs from the surrounding fluid and so their light is refracted. Different objectives mounted on a carrousel allow for the selection a specific measuring range by software.

The most prominent feature is an exposure time within the sub-nanoseconds regime and an image capturing frequency of up to 500 frames per second. This allows the use of proven dry disperser RODOS for the characterization of finest, cohesive powders. And based on a great number of measured particles, a high confidence level for measuring results is achieved.

Our powerful evaluation software supports the simultaneous determination of all relevant size and shape characteristics. Measures for length, width, equivalent circumference and diameter of a circle describe the size of a particle. Sphericity, aspect ratio and convexity provide information about the shape. Fibres can also be properly evaluated with length, diameter, straightness and elongation. A particle gallery together with user-defined screening criteria facilitate the creation of specific and meaningful reports.

In addition to the combination of QICPIC with the powerful disperser RODOS, the combination of QICPIC with gravity disperser GRADIS for coarse dry products is also available. Fibres are dispersed and analysed with QICPIC and FIBROS. The wet dispersing unit LIXELL is specially developed for suspensions and emulsions. OASIS combines dry and wet analyses in one unit.

Applying components of highest performance our modular sensor QICPIC develops the full power of dynamic image analysis. The powerful and proven system components of QICPIC are also available for process integration. With PICTOS & Co disperser and sensor of QICPIC are integrated into one robust body, developed specifically for dry and wet on-line applications. Elaborate technologies for representative in-line sampling like TWISTER and many possibilities for customer-specific sample feeding make image analysis an excellent option for process control.