Know the particle size and shape of your coffee grounds for a perfect coffee taste

Across the world there are about 40 different known varieties of coffee beans which, in various blends and degrees of roasting, determine flavour, taste and brewing behaviour of the hot speciality. In addition to the selection of the green coffee, roast and blend, the grinding degree of the coffee powder is crucial for coffee preparation. If, for instance, you are preparing an espresso or Turkish coffee, a very fine grind with grain sizes below 1 mm is required; for common drip brewed and filtered coffee particle size is below 1.5 mm and for Scandinavian, French press or American brewed coffee it is just below 3 mm.

Inspired by capsule technology, the coffee industry is constantly bringing new types of coffee onto the market that continue to stimulate consumption. This increases the requirements for quality control, particularly with respect to the size distribution of coffee powder. Another challenge is the strong internationalisation of coffee producers, which makes comparability of analyses at different locations necessary. Industrial grinding of coffee and frequent changes in variety require a continuous, partially automated control of the particle size distribution to ensure consistent product quality.

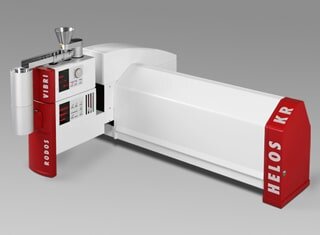

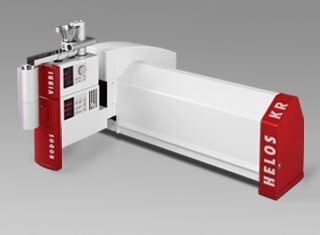

Along with traditional sieving, laser diffraction is the most common method used for determining particle size distribution in coffee processing. Laser diffraction, in combination with RODOS dry dispersing, demonstrates its strengths in the quick and precise grain size analysis with HELOS in the laboratory as well as with MYTOS in the process.

Learn more about particle sizing of coffee. Watch the video!

The high sample throughput in RODOS dispersion means it is also possible to measure larger sample quantities of up to 100 g. This ensures high statistical significance and unrivalled repeatability and comparability of measurement results – including at different production sites. The fast measuring cycle and simple, automatic cleaning of the measuring section allow for up to 60 measurements per hour.

- Efficient dispersion of oily coffee powder

- High sample volume for sufficient statistics

- Fast and reproducible measurement without additional sample preparation

- Avoiding a sample carry-over through reliable cleaning

- Recovery of the sample

Better particles with best instruments

Our laser diffraction and additional image analysis systems cover the entire range of particle size and particle shape characterisation in coffee. As the pioneers of dry particle measurement technology, we are widely established on the international coffee market with numerous product-adapted and process-oriented installations. Lab applications in product development and quality control (off-line), installations in laboratories with automated sample feeding (at-line) and the real-time measurement of the particle size distribution in the grinding process (on-line) ensure the best product qualities through timely intervention in the production process. Dry measurement enables high sample throughputs with a minimum sample preparation effort and little cleaning overhead and – if desired – sample recovery. Measurement methods developed for various product qualities can easily be transferred to other systems as a standard operating procedure (SOP). Consistently high product qualities can be precisely controlled, thus justifying the confidence in the premium quality of your coffee products.

Robust instrument design and professional system maintenance by our qualified service staff ensure consistently outstanding quality and sustainability of the measuring systems. International coffee producers with widely distributed production sites rely just as much on our expertise as smaller or medium-sized providers of regional coffee specialties. The leading manufacturers of professional grinders for the coffee industry and for the use in fully-automated coffee machines also rely on our expertise in particle characterisation.

Download application note for detailed information

Are you interested in additional content? Please register an account. After confirming the registration link brochures, application notes and other documents on particle measurement will be available for download.

Single particle detection with image analysis

The analysis of the particle shape also plays a key role in particle size analysis for the product development of coffee and for the development of coffee grinders and grinding machines. Dynamic image analysis with QICPIC and dry disperser RODOS records around 1 million particles within one minute and thus provides excellent statistical reliability of the measurement results. Powerful evaluation modes for size and shape, as well as various definable selection and filter criteria support the identification of certain fractions within a sample. In addition to the quantitative evaluation and representation in distribution diagrams, a particle gallery and the particle video recording are also available for qualitative analyses.

Watch the particle film about the representation of coffee grinding

Particle film of a measured coffee sample with identifiable fractions | Dust portion below 100 µm | Optimum coffee powder from 100 µm to 1,000 µm | Low proportion of coffee skins above 1,000 µm

Application strengths

- Unique RODOS dry dispersion

- High sample throughput for a rapid measurement (< 10 s) with large sample volumes (> 100 g)

- Coordinated measurement range for various degrees of grinding

- Sample recovery using a central extraction system or cyclone

- Very good repeatability and good system-to-system comparability through large sample volume

Customer benefits

- Pure coffee of the highest quality

- Optimal production within specifications

- Precise and rapid control of particle size for consistent product quality

- Simple exchange of results between different locations

- Quick amortisation when eliminating screening

Application strengths

- Easy connection to existing sampler

- Perfect RODOS dry dispersion with controlled dispersion forces

- VIBRI dosage with reliable cleaning system for automated operation

- Reproducible and sensitive measurement results through auto-focus detector

- Comparable results for laboratory analysis with HELOS laser diffraction

- High analysis frequency with up to 30 measurements per hour

Application strengths

- Representative sampling from pneumatic conveyor with TWISTER

- Perfect RODOS dry dispersion with controlled dispersion forces

- Reproducible and sensitive measurement results through auto-focus detector

- Comparable results for laboratory analysis with HELOS laser diffraction

- Very high analysis frequency with up to 60 measurements per hour

Customer benefits

- Reliable real-time analyses to optimise the roller mill gap

- Optimised production with consistently perfect particle size

- Avoidance of faulty batches

- Savings from mixing silos

- Location-independent comparison of coffee grinding

Application strengths

- Complete and reproducible pressure air dispersion with RODOS

- Quick measurement | High sample throughput | Easy cleaning

- High statistical reliability with over 1 million recorded particles within 1 minute

- High dynamic measurement range

- Powerful evaluation modes for size and shape

- Various display options of distribution diagrams

- Variety of user-specific selection and filter criteria for identifying certain fractions

Customer benefits

- Reliable identification, even of the smallest proportions such as coffee bean skins

- Optimisation of grinder based on statistically reliable results and vivid images of particles in particle gallery or in the particle film

- Improvement of processes in industrial coffee processing

- Higher and uniform quality of grinding products