Particle size and particle size distribution with laser diffraction for lab applications ranging from below 0.1 µm to 8,750 µm

The proven HELOS series – with its classical parallel beam laser diffraction set-up – offers a powerful technology for particle size distribution analysis of powders, granules, suspensions, emulsions, sprays and numerous other particulate systems. A size range from below 0.1 µm to 8,750 µm is mastered. The modular sensor reveals its true superiority when operated with feeding and dispersing systems, that guarantee for best adaption to the product sample.

The complete spectrum of ranges R1 to R8 proves the strong concept of the measuring range segmentation. Reliable insight into all details of the samples to be analysed can only be achieved with selection of the optimum measuring range. Typical disperse products rarely span over more than two decades. Even for these special products the concept of the multi range combination holds since the introduction of the innovative R-series.

Best possible agreement with absolute values is achieved using the more powerful evaluation algorithms of FREE and MIEE. Extremely short analysis times – especially for dry dispersion – are maintained and even for the combination of four measuring ranges the time requirement typically necessary for suspension analysis is kept. The R-series of our particle size analyser HELOS sets new benchmarks for precision and accuracy. Latest improvements comprise enhanced application of parameter-free Fraunhofer evaluation down to the submicron regime (below 1 µm). Laser diffraction is now even closer to absolute standards. Continually, industrial requirements and limits are considerably outmatched. The use of more stable inversion procedures in combination with best optical models and the inclusion of signal statistics brings the laser diffraction even closer to absolute standards. Continually, to the specifications of ISO 13320 "Particle size analysis - laser diffraction methods" the requirements and limits are considerably outmatched.

- Laser diffraction fully compliant with ISO 13320 for the complete size range from 0.1 µm to 8,750 µm

- Highest precision and resolution of the particle size distribution by 8 measuring range modules

- Automated multi range combination for broad distributions

- Modular design structure with a great variety of dispersing and dosing units for flexible adaption to the sample

- 2,000 particle size distributions per second are acquired by using the integrated time resolved mode

- Unrivalled reproducibility of results and excellent system-to-system comparability

- Powerful evaluation with parameter-free Fraunhofer or with Mie, if optical properties are known

Download more information about HELOS family

Forgot your password?

Please enter your username or email address. Instructions for resetting the password will be immediately emailed to you.

Are you interested in additional content? Please register an account. After confirming the registration link brochures, application notes and other documents on particle measurement will be available for download.

Modular system design for product-specific particle size analyses

The precondition for convincing and reliable measuring results are based upon product-adapted and reproducible sample analyses. A product adaption will be achieved if particle collectives are dispersed and supplied to the measurement in their original condition: dry powders and granules, suspensions and emulsions wet, as well as sprays and inhalants as aerosols – without time-consuming preparations. The modular system design together with a great variety of dispersing and dosing units provides a flexible adaptation to the most diverse industrial and research applications:

HELOS-R Series

The HELOS family includes 3 laser particle sizer:

| Sensor | Measuring range/ Modules | Applications |

|---|---|---|

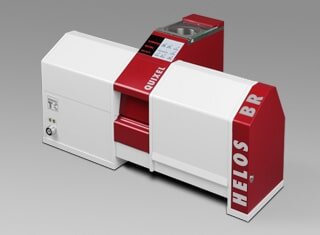

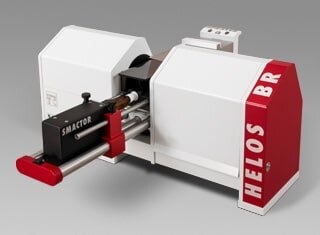

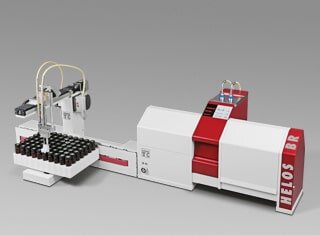

| HELOS/BR | 0.1 - 875 µm/ 5 | powders, suspensions, emulsions, sprays & aerosols |

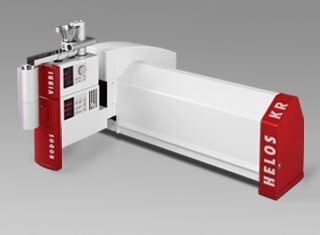

| HELOS/KR | 0.1 - 8,750 µm/ 8 | powders, granules, suspensions, emulsions, sprays & aerosole |

| HELOS/KR-Vario | 0.1 - 8,750 µm/ 8 | powders, granules, suspensions, emulsions, sprays & aerosols, special applications |

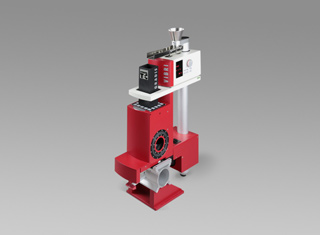

HELOS/BR is the shortest model version of the instrument family and finds room on every laboratory table. It integrates up to 5 optical modules for a measuring range from below 0.1 µm to 875 µm. A multitude of measuring tasks are fulfilled reliably and offers measuring confidence even to the coarser particle range. The laser analyzer can be used with all HELOS dispersing units.

ConfigurationS WITH HELOS/BR

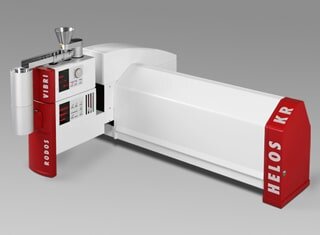

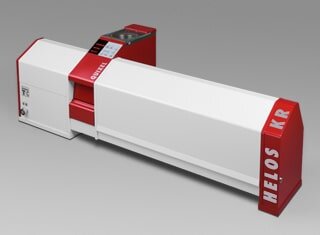

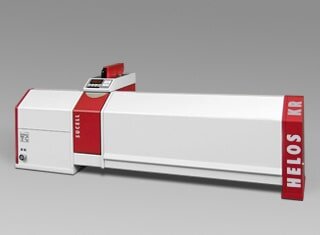

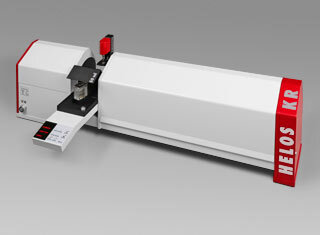

HELOS/KR is the longest model version of the instrument family and integrates up to 7 out of 8 optical modules for a measuring range from 0.1 µm to 8,750 µm. All measuring tasks are fulfilled reliably in the submicron range as well as for coarsely dispersed material. The laser diffraction sensor can be used with all HELOS dispersing units.

- Measuring range from 0.1 µm to 8,750 µm

- Long optical bench | 110 cm footprint

- Modular design combinable with all HELOS dispersing units

- Unlimited performance

Configurations WITH HELOS/KR

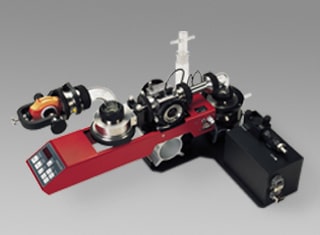

HELOS/KR-Vario is the most flexible model version of the family and is suitable for laboratory tasks as well as for technically complex measuring arrangements. It integrates up to 7 out of 8 optical modules in the measuring range from 0.1 µm to 8,750 µm. The open measuring zone, which can be extended to several meters, supports the flexible adaptation of the optical measuring system to individual customer requirements for demanding applications in laboratory or pilot plant environments. HELOS/KR-Vario is perfectly suited for technical spray applications, e.g. in the agricultural sector or for in-situ measurements in wind tunnels with complex setups.

- Measuring range from 0.1 µm to 8,750 µm

- Modular design combinable with all HELOS dispersing systems

- Optical bench with variable measuring zone from 123 mm to 1,400 mm

- Measurement of technical sprays in a measuring range from 0.5 µm to 3,500 µm

- Measuring zone in free arrangement expandable to over 1,400 mm

- For analyses in laboratories, pilot plants, wind tunnels and at process lines