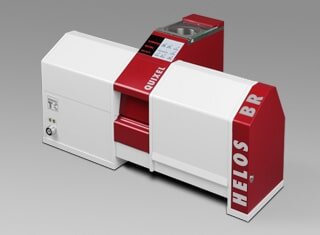

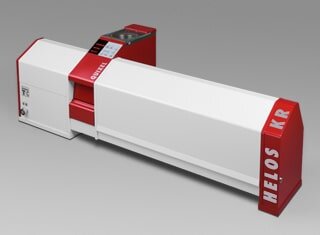

Particle size analysis for suspensions with fine particles ranging from 0.1 µm to 875 µm and reprocessing of the dispersing medium for reuse

Together with the powerful and fully-automated wet dispersion unit QUIXEL, the compact laser diffraction sensor HELOS/BR offers fast and reproducible particle size analysis for fine dispersed suspensions from 0.1 µm to 875 µm. All measurement and dispersion parameters can be entered using the operating panel or the software and be saved as retrievable measuring methods (Standard Operating Procedures (SOPs)).

QUIXEL is equipped with an optionally temperature-controlled stainless steel basin, centrifugal pump, ultrasonic generator, tubeless measuring circuit and application-specific flow cuvettes with layer thicknesses of 2 mm and 6 mm. The basin geometry and the flow control guarantee a stable suspension and minimise the risk of sedimentation even in cases with broad distributions and particles with high density. Thanks to the lowerable bottom of the basin, quick draining and cleaning are possible in just a few seconds even with high-viscosity dispersion media.

In order to recover and reuse environmentally harmful and expensive dispersing media, it is possible to incorporate a liquid reprocessing system in the QUIXEL circuit in the form of LIQIBACK. The separation of solid particles is performed using two temperature-controlled sedimentation containers and downstream filter stages with filtration grades of 1 µm and 0.45 µm. An impeller pump automatically supplies QUIXEL with the reprocessed dispersing fluid.

Different materials are available for gaskets, tubes and impellers to ensure that the chemical resistance is matched to the dispersing fluid (EPDM, FKM). The other equipment options for cuvettes, temperature control and materials in contact with the product open up a wide range of potential applications.

The modular concept of the HELOS laser diffraction series allows this configuration to be systematically expanded with numerous dispersion units and dosing options to open up many more product-appropriate measuring applications.

- Particle size and particle size distribution

- For fine dispersed suspensions

- For analyses in the quality or production laboratory | Also process-oriented

- Variable analysis volume from 300 ml to 1,000 ml in a circuit

- 5 high-resolution measuring ranges from 0.1 µm to 875 µm | R1 to R5T

- Automatic adjustment of all dispersion parameters | Software-controlled

- Integrated sonication | Energy input 0 to 60 W

- Heating and cooling options | Temperature-controlled from 0°C to 60°C

- Recovery of the dispersing medium by means of a filtration system